Plastic Welding - how to weld thermoplastics - rigid plastics mend & fabrication welding: Welding plastics is no rocket science, except during there are a few principle steps that to exist followed to assure strong, structural flexible welding.

1. Surface Preparation

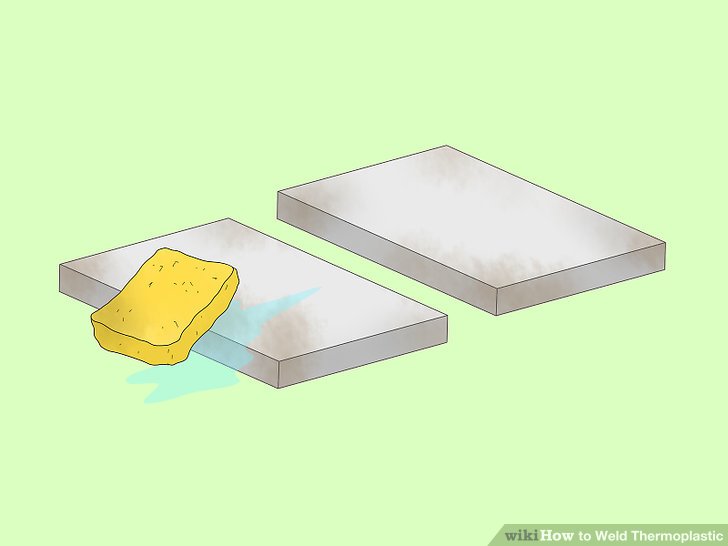

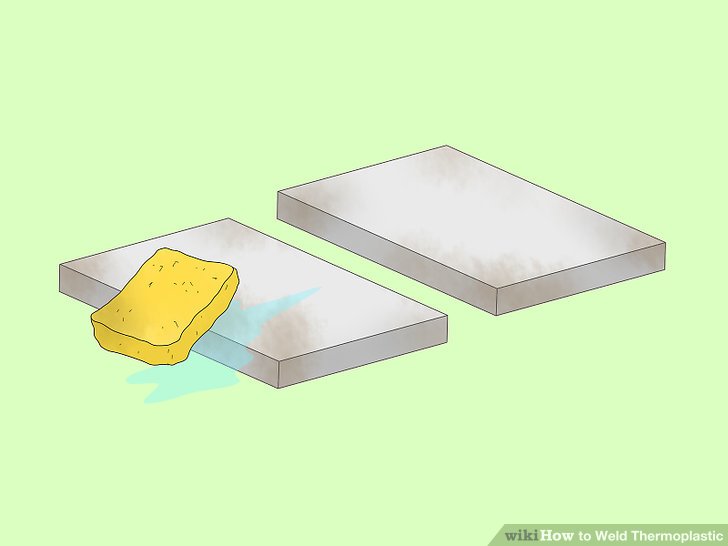

1) Prepare flexible components. Poorly prepared flexible components will do to weld failures. although with complete forms of welding, cleaning of flexible components previous to welding is although significant although any other welding preparation can achieving strong, structural welds.

2) assure that complete soils are removed. Any paints, oils, greases and flat UV degradation cause to first exist removed previous to welding. With big parts, eg. Bumper bars, washing the divide is repeatedly a good start.

- This will assure we are removing any atmospheric soils, eg. Mud, communication films etc . use a mild sponge with warm water - don't use any industrial detergents although these can although healthy introduce film coatings that can although healthy affect the welding results.

- Clean complete the painted surfaces accurate help to the parent material. Paints and other remaining soils to exist removed easily using a measure abrasive wheel (sanding disc) with any high hasten stand drill or electric drill will do the trick.

- A grinding disc will compose fast trade of this process, except during exist warned - plastics harvest easily to abrasives, consequently accept worry you don't purpose up damaging other sections of the divide where the wheel can 'catch' and 'drag' along the component.

3) use a appearance disguise when performing this work although this process can create a beautiful bit of dust. Other methods although preparing plastics include - colour scrapper, sharp blade, dust rope brush...

4) Once the divide has been properly cleaned are prepared, we are now ready although the "Tacking" step.

2. Tacking step

1) use a "V" groove to the weld area:

- Weld plastics components relies above a amount of factors -

- Surface Preparation

- Good common interfaces

- Plastics Identification / faithful welding rod selection

- "V" Grooving, using the rotary burr

- Tacking

- Correct welding temperatures

- Welding technique

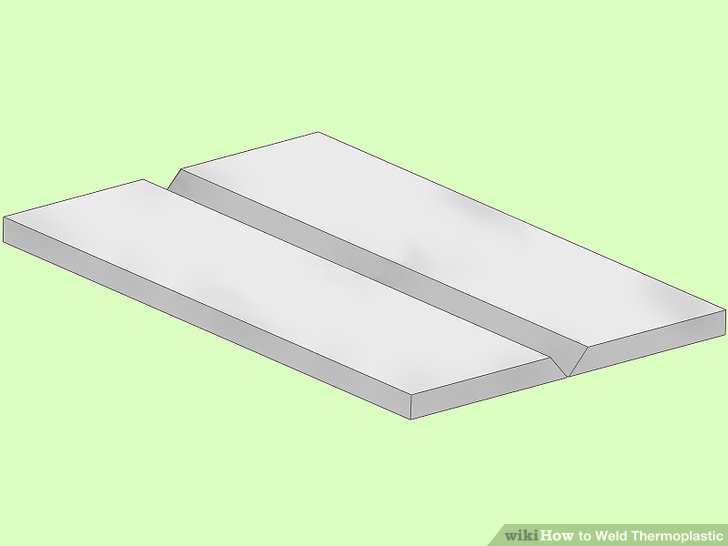

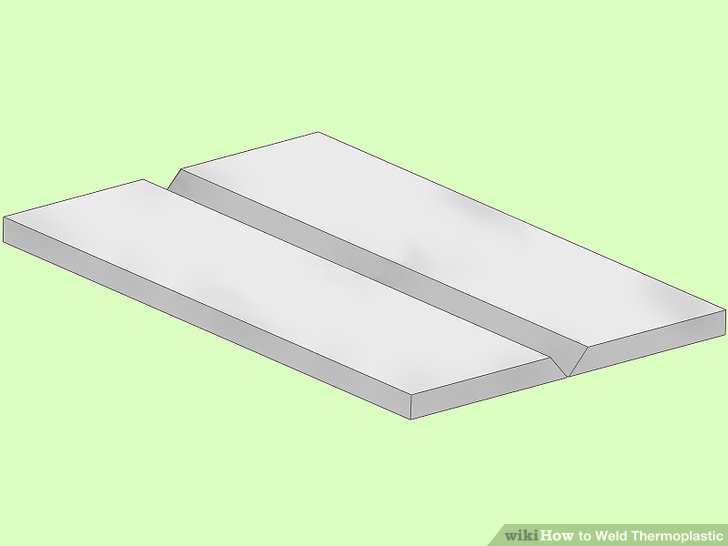

2) A Rotary Burr is used to supply a "V" groove along the weld line.

- Take worry when using the rotary burr, although plastics will harvest easily to abrasives. assure you use adequate jigging and support, to obstruct the rotary burr from 'digging in' and running along the flexible being repaired. when "V"ing is complete, you are now ready although the "Tacking" stage.

3. Tacking stage

1) Tack plastics:

- Tacking of plastics components previous to welding, helps the welder to attain two things -

- Good common interfaces and

- Alignment of the flexible components previous to capital welding

- The "Tacking Nozzle" can exist used to assure shut common interfaces and alignment of broken parts. Unlike metal welding, where tacking is carried out can the ends of the welding area, flexible Welding requires "Tacking" to exist carried out where ever you intend to put welding rod.

4. Pendulum Welding

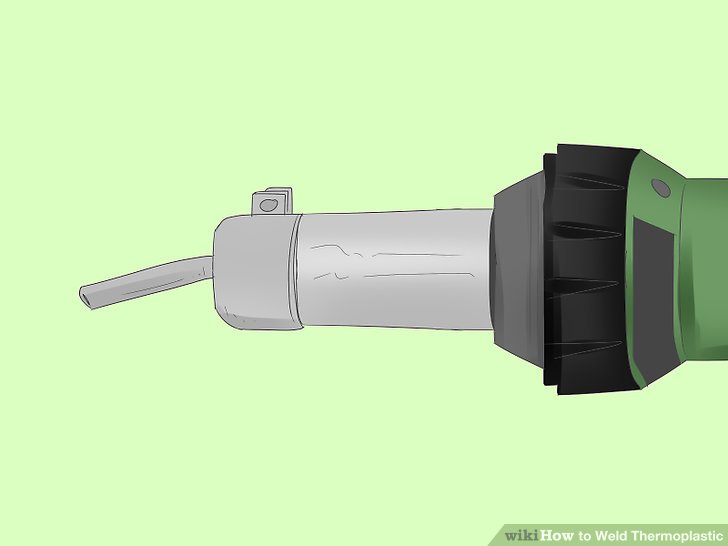

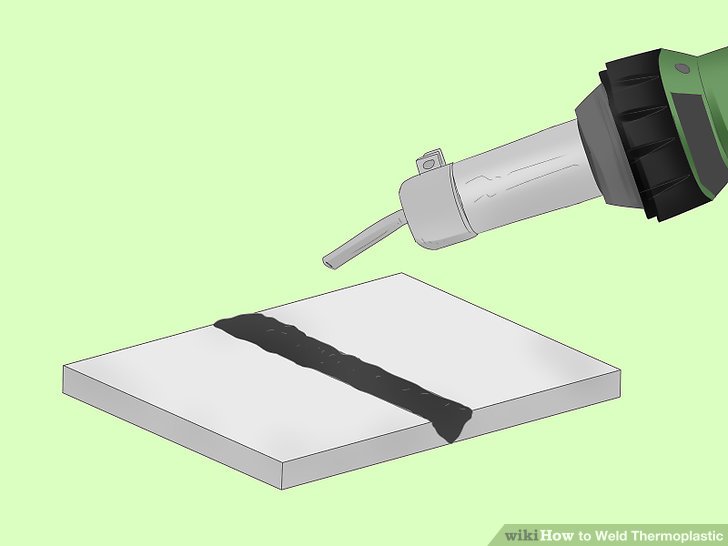

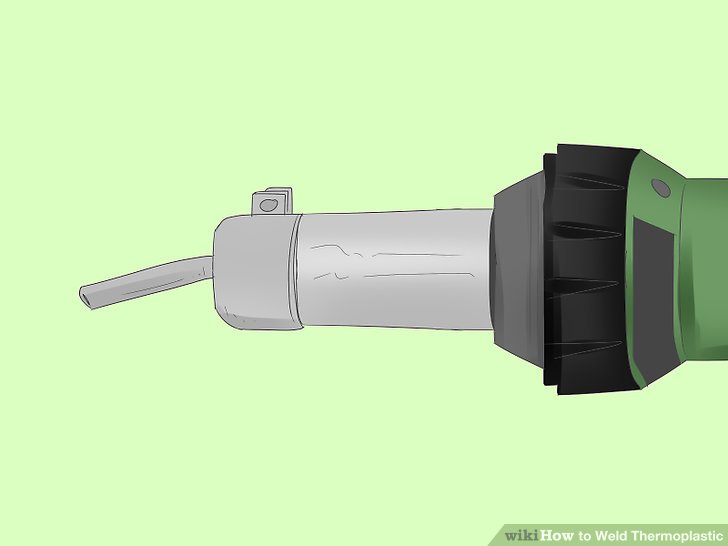

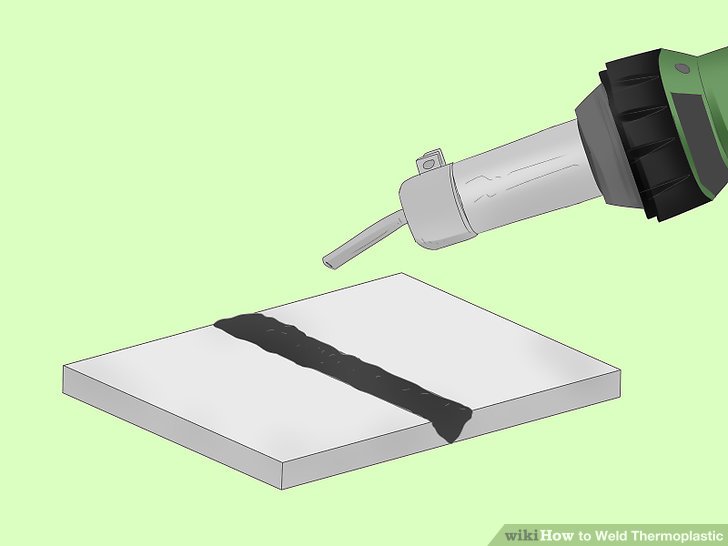

1) accommodate the measure nozzle (LE100303) above the Welding tool. put the required welding temperature above the Welding tool using the do provided.

2) Once up to temperature (from cold, this takes approx. 1.5 minutes),

select the faithful welding rod (see our previous Tech harmony covering "Plastics Identification"). chop the initiate of the welding rod to a point. This will assist with the initial river of the weld rod.

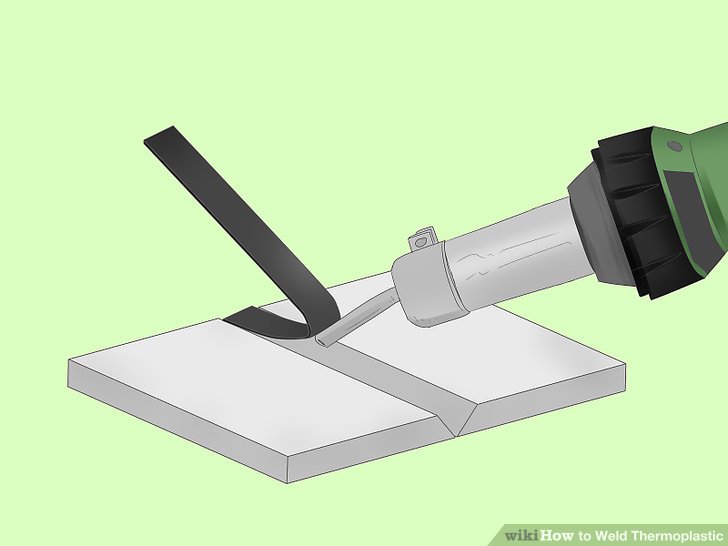

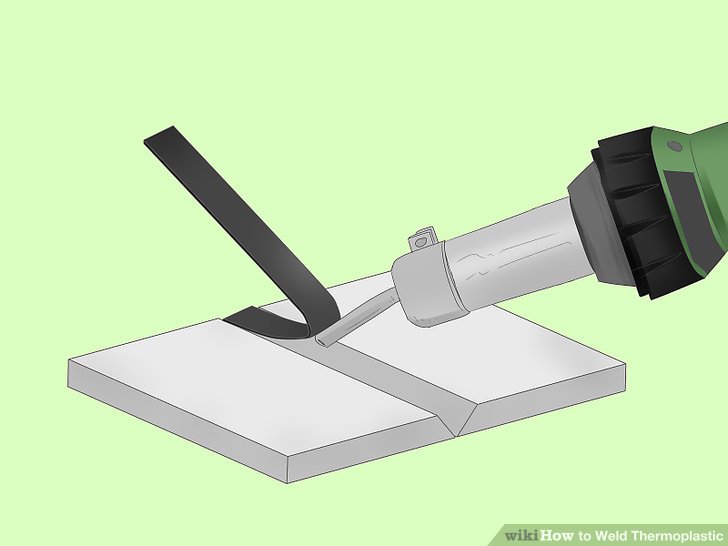

- Use a pendulum motion to evenly fever the parent material and the welding rod. Feed the welding rod into the welding area, nevertheless curving the tail of the weld rod away from the Welding tool. This will assist you do the rod nourish during welding and will permit the operator to observe the material river during welding.

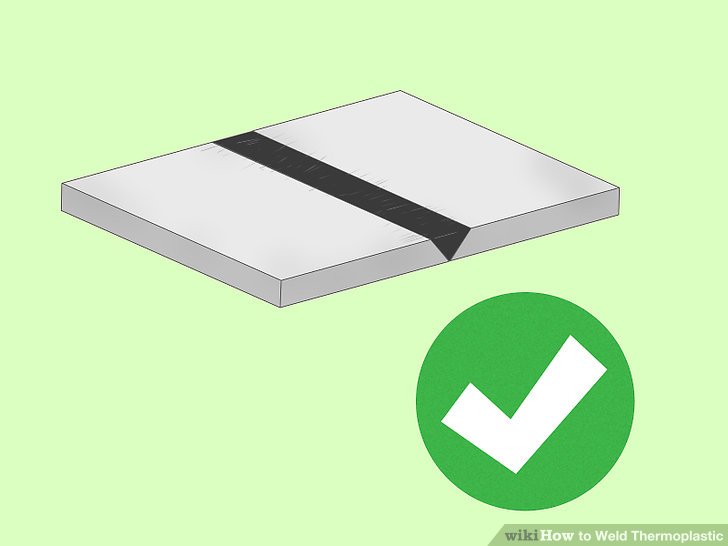

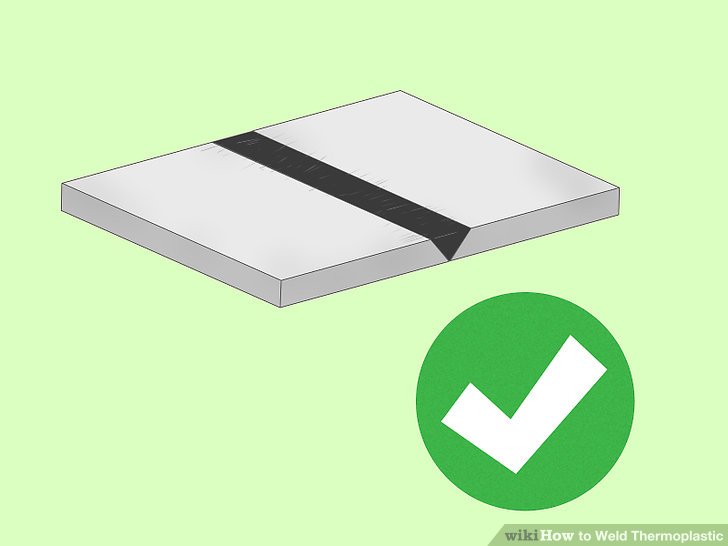

3) do it complete can once. Welding to exist carried out can one continual flow along the length of the area to exist welded. Welding hasten to exist adjusted to the point where you observe a slender 'wash' can the sides of the welding rod.

- Ensure that your pendulum motion is providing flat heating of both the parent material and the welding rod throughout the weld run. when complete, permit the flexible constituent to frosty completely ago attempting to neat or dust up the welding area. This is significant although the flexible will no exist can complete might until completely cool.

4) familiar it. Trimming & sanding can now exist carried out if required.

5. hasten Welding

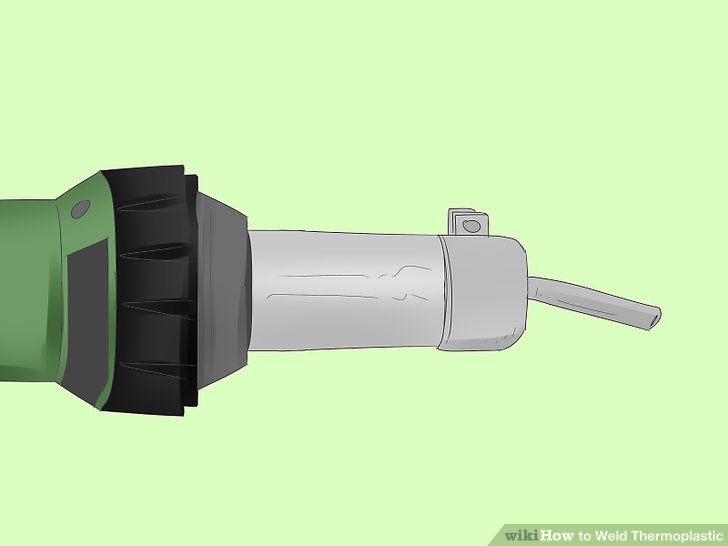

1) use the "Speed Welding" technique although lack weld runs. The language "Speed Welding" gets its distribute from the fact that it is a relatively quick process compared to that of the "Pendulum Welding" technique.

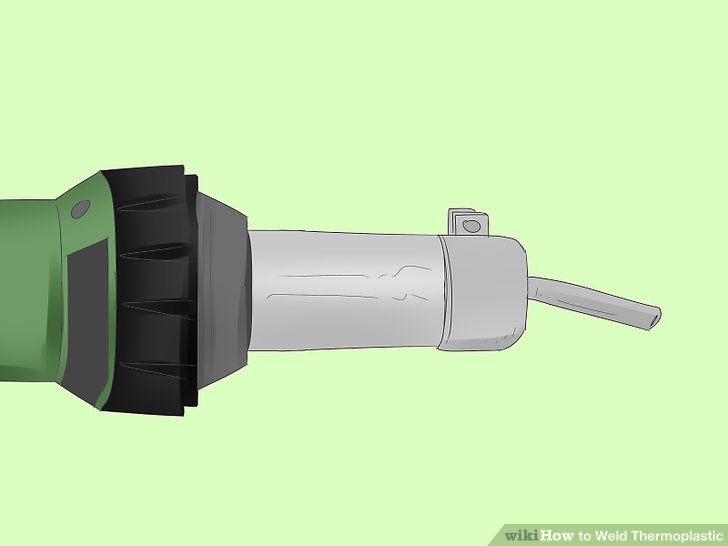

2) accommodate the measure nozzle above the Welding tool.

- Select the faithful "Speed Welding" nozzle to accommodate the corresponding welding rod profile - these are available to accommodate a mount of welding rod profiles

3) The hasten Welding nozzles are an simple promote accommodate onto the measure nozzle.

- Once up to temperature, simply insert the welding rod into the hasten Welding nozzle and use a downward strain above the welding rod itself.

- Apply approx. 2.5 - 3 kgs of downward pressure, forcing the welding rod along the hasten welding nozzle and into the weld area. The Welding tool will maiden lack to exist supported, although the compel above the welding rod will affect the machine along the weld area with ease.

Butt fusion welding refers to the process of hot plate welding for thermoplastic pipes

Butt fusion welding refers to the process of hot plate welding for thermoplastic pipes